Custom Plastic Thermoforming Services

Since 1992, FormTight has had experience with a variety of custom plastic packaging services ranging from small blisters to industrial equipment coverings. Whether it be a custom retail clamshell, custom medical device tray, or custom food shipping tray, we can help produce a one-of-a-kind package that is perfect for your project.

Check out the selection of custom plastic thermoforming services we offer at FormTight.

Custom Plastic Packaging Services

Clamshell Packaging

View Clamshell Packaging

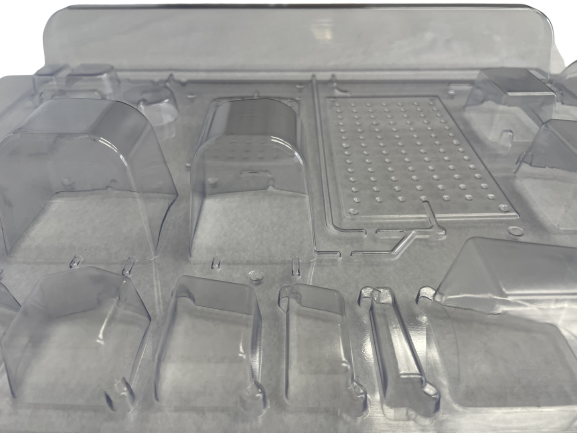

Thermoformed Trays

View Thermoformed Trays

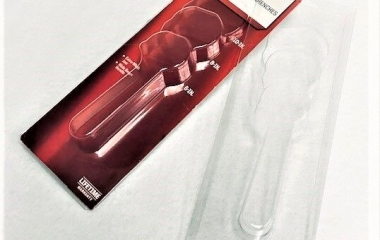

Blister Packaging

View Blister Packaging

POP Retail Displays

View POP Retail Displays

OEM Parts

View OEM Parts